Concept Turn 60

EQUIPMENT

Technical data

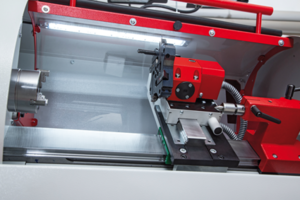

Work area

| Travel in X/Y/Z | 60/-/280 mm |

| Bar diameter | 15 mm |

| Max. part length with tailstock | 60 mm |

| Swing over bed | 130 mm |

| Tool cross-section for outer machining | 12 x 12 |

| Tool cross-section for inner machining | Ø 10 |

| Rapid motion speeds in X/Y/Z | 3/-/3 m/min |

| Work feed X/Y/Z | 0 - 2 m/min |

| Feed force in X/Y/Z | 1000 N |

Main spindle

| Max. speed | 300 - 4200 rpm |

| Spindle nose | EMCO |

| Max. drive power | 1,1 kW |

| Max. torque | 10 Nm |

Tailstock

| Quill travel | 35 mm |

Tool turret

| Number of tools | 8 |

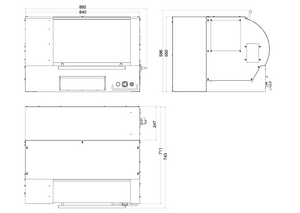

General data

| Dimensions (LxWxH) | 895 x 745 x 550 mm |

Overall dimensions/Work space

Options/Accessories

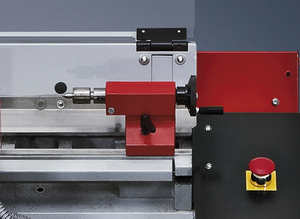

Manual Tailstock

The tailstock serves to support long workpieces by means of a centering point. Tailstock and centering tip are available as an option. Quill stroke: 35 mm Quill diameter: 22 mm Quill cone: MT 1Machine base with swivel table

The machine base is equipped with a pull-out drawer for tools and aids and a holder for the coolant system and PC tower. PC keyboard and monitor can be set up on the swivel table.Comprehensive selection of tools

e.g. roughing tool, copying tools, drill holder, inner threading tool, various drills and indexable inserts for various machining materials.Easy2control

“Easy2control” adds a range of attractive applications to the successful interchangeable control system used in EMCO training machines.

Suitable for use in machines and simulation workplaces alike, it displays additional control elements directly on the screen and, when used together with a touchscreen monitor, provides the ideal input interface.

With support for a wide range of keyboard variants, customer-specific screen layouts and tailored solutions for individual customers, Easy2control represents a promising and highly flexible extension to the modular EMCO training concept.

The interchangeable controls are represented using an on-screen keyboard, which makes switching between different control systems even easier and quicker.

In the DEMO version of WinNC, Easy2control can be activated without a license key during the installation process or afterwards using the EMConfig configuration tool.

Easy2operate

Portable Machine Operating panel to operate the machine via hardware, includes axis buttons, feed override switch, mode switch etc. together with EMCO Easy2control.Automation

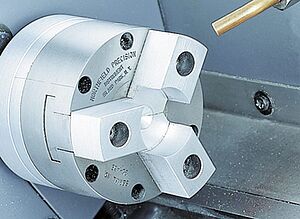

Pneumatic unit and pneumatic chuck

The pneumatic unit serves as preparation for the automatic door and the pneumatic chuck, which consists of a pneumatic full clamping cylinder including 3-jaw power chuck and blow-out deviceElectromechanical tailstock

The electromechanical tailstock has a quill stroke of 15 mm and a end position control.Automatic door

The chip protection door can be opened and closed program-controlled or by pressing a button via a pneumatic cylinder. The door position is monitored using limit switches.Integration into FMS and CIM systems

The robotics interface can not only control the periphal equipment (such as automatic door, vice, etc.) but also connect the machine to other machines or devices (e.g. loading and unloading robots). The DNC interface allows programs to be transferred and started from the master computer.Software/Control

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Training_Software/winnc_und_erweiterungen/emco-winnc.png)

EMCO WinNC

The unique concept of the interchangeable control can be fitted to all Concept machines. In doing so, the user is trained on all CNC industry controls that are common to the market.

The result: CNC technicians are flexible to work in a variety of settings.

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Training_Software/winnc_und_erweiterungen/emco-win3dview.png)

EMCO Win3D-View

Win3D-View is a 3D simulation for turning and milling and is available as an option in addition to the WinNC Control. Graphic simulations of CNC controls are designed especially for industrial experience. Win3D-View displays exceed industry standards. Tools, blanks, clamping devices, and work processes are highly realistic. The system checks the programmed travel of the tool to prevent collision with clamping devices and blanks.

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Training_Software/winnc_und_erweiterungen/emco-cam-concept.png)

EMCO CAMConcept

CAMConcept is innovative software for complete CAD/CAM and CNC training, from design to manufacture. CAMConcept incorporates both the functions of a professional CAD/CAM system and the advantages of a special training program. All core CAD program functions are available. Graphic displays of CNC cycles allow quick programming, while simulations and collision checks ensure that control programming is safe.

![[Translate to en:] Concept Turn 60](/fileadmin/_processed_/f/5/csm_emco-drehmaschine-ausbildung-turning-machine-training-concept-turn-ct60_14c9f34b4d.png)