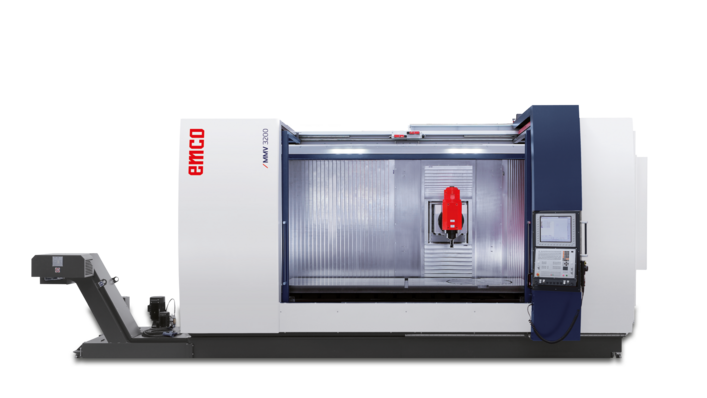

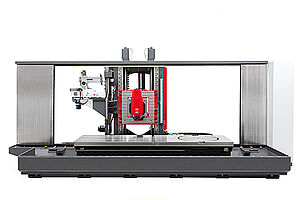

Machining Center MMV 3200

EQUIPMENT

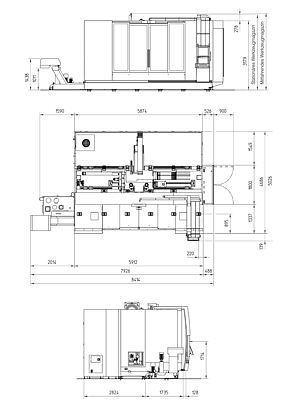

Technical data

Work area

| Travel in X/Y/Z | 3200/1000/950 mm |

| Distance spindle nose | 0-950 mm (vertical) / 250 - 1200 mm (horizontal) |

| Number of axes (basic machine) | 4 or 5 axes |

| Rapid motion speeds in X/Y/Z | 50 m/min |

| Clamping area | 3500x1050 mm |

| Max. table load | 5000 kg |

Tool change

| Number of tool stations | 40/60-120 |

| Max. tool diameter | 92 (125) mm |

Milling spindle

| Max. speed | 50-18000/50-10000 rpm |

| Max. torque | 125 Nm (S1), 170 Nm (S6-40%) |

General data

| Dimensions (LxWxH) | 8414x5026x3458 mm |

| Machine weight | 24000 kg |

Highlights

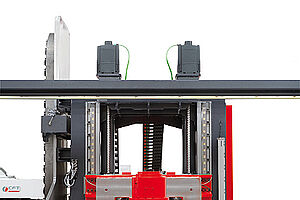

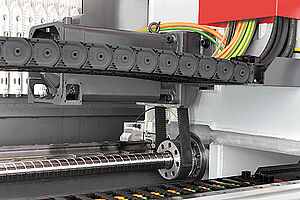

Tool magazine

Available with turret configuration on 3-, 4- and 5-axis version, or with alongside columnconfiguration on 4- and 5-axis version. Tool change on turret configuration with dual arm grippers at the X-axis limit, with 40 tool stations (optional 80). Tool change on the alongside configuration fast and safe, all along the X-axis and at the extreme limit of the Z- and Y-axis. Up to 120 tool stations. An external tool changer „tower“ is available upon request.

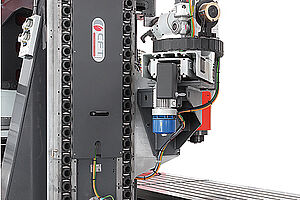

Millingspindle

The machine is equipped with a liquid cooled motor spindle with compelling performance specs. At spindle speeds of 15000 rpms, a power rating of 46 kW, and a torque of 170 Nm, the machine is also suited for heavy-duty machining. A motor spindle 18000 rpm is available with HSK A63.Z-axis travel

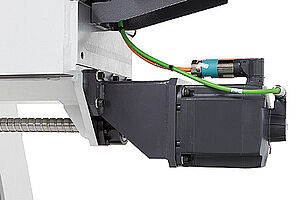

In order to attain precision Z-axis rapid travel at speeds of 40 m/min, and due to its largemass, this axis is powered by two ball screw drives and two motors in a master-slave configuration.

Y-axis

The Y-axis has a ram configuration. This design uses long way guides in order to attain the required rigidity. Its high precision is guaranteed by the motor installed direct drive on the screw.Machine frame

The machine bed is made of welded high quality steel. This ensures the required rigidity of the machine base, and also facilitates vibration dumping.X-axis

Equipped with rotating nut ballscrew and fixed screw. The positioning accuracy is guaranteedby the standard linear scale.

Control unit

The operator panel can travel, rotate and be adjusted in the direction of the work space.This ergonomic design provides ideal working conditions for the operator.

B-axis

The B-axis is driven by a torque motor, therefore achieving highly dynamic axis travel withinthe pivoting range of +/- 120 degrees.

Overall dimensions/Work space

Options/Accessories

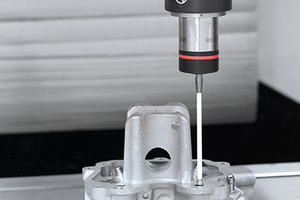

MEASUREMENT SYSTEM

Tools measurements to reduce setup times during tool changes, as well as work piece measurements to verify dimensions or to find zero locations. The work piece measurement is radio.Large Work Area

Thanks to the large work area, it is possible to customise the machine with a wide variety of options, e.g. with a partition for pendulum operation, a rotary table, a tailstock etc.Band filter system with high-pressure coolant pumps

A coolant pressure of 25/40/60/80 bar can be set as necessary. This enables coolant-fed drilling and milling tools to be used to their best advantage.

Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

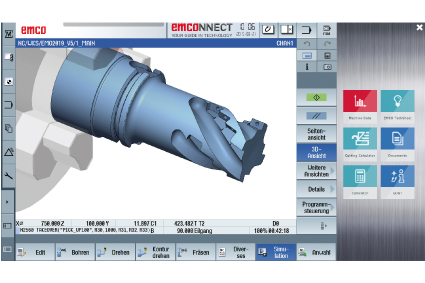

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

Heidenhain TNC 640 (MMV series)

TNC 640 Heidenhain offers besides the milling operations also combined milling and turning operations. It is particularly suitable for Mill-Turn, HSC- and 5 axis operations at machines up to 18 axes.

Details:

- 19'' TFT colour display

- Optimised user interface

- Interactive fast choice of functions

- Numerous machining cycles

- Innovative graphic simulation

- Improved motion control and short block processing time

EMCONNECT - Digital Process Assistant

For increased productivity and efficiency in production.

EMCONNECT facilitates easy access to digital production – all important information and systems are accessed centrally on the machine. The familiar NC control and hence the familiar operation of the machine remain unchanged.

A clear and compact overview of the machine state, the machine data and the operating mode is available at a glance thanks to the emcoNNECT Dashboard. The hardware basis of the EMCONNECT control centre is a 22“ multi-touch display teamed with an industrial PC and a keyboard including HMI hotkeys for easy and intuitive operation via a user interface optimised for touchscreen use.

Included as standard equipment in the Siemens machine version (Sinumerik ONE).