EMCONNECT

EQUIPMENT

Highlights

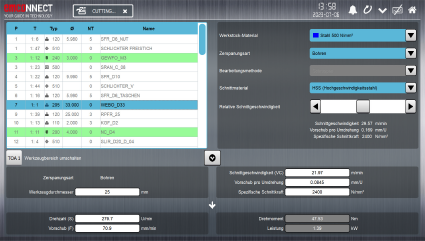

EMCONNECT DASHBOARD

Clear and compact - machine status, machine data and operating mode at a glance.

/ Depending on the machine configuration and active mode (JOG, MDA, AUTO).

/ All relevant data such as active program, selected tool, axis positions, etc. at a glance.

/ Colored visualization of the current spindle utilization and override values.