Experience & projects in turning

COMPLETE MACHINING AND DIGITISATION AS THE KEY TO SUCCESS

Special projects require special partners

EVVA and EMCO have found in this collaboration the opportunity to make the most of their respective expertise: the ability to respond quickly and flexibly to customer requirements, the availability of advanced machinery and processes, and a shared approach to innovation, automation and digitalisation.

The challenge was as clear as it was ambitious: dry machining brass components with micro-holes (Ø 1.8 mm), minimising set-up times, handling a wide variety of parts and connecting everything to a future fully digitalised production environment.

For EVVA, this step marks a new milestone in its history of innovation: digitising processes from production to ERP. In such a strategic endeavour, choosing the right partner is crucial.

EMCONNECT as the best platform

After careful consideration, EMCO emerged as the ideal partner. Not only because of the long-standing, solid partnership already in place for shop floor equipment, but also because of the EMCONNECT software platform: flexible, integrated and perfect for the digitalisation projects EVVA intends to implement.

Joint research projects

The partnership is also strengthened by the collaboration of both companies in research projects at the Vienna University of Technology: In the Austrian Centre for Digital Production (CDP) laboratory, companies and researchers develop solutions for automation and cyber-physical production systems. EVVA and EMCO contribute to these projects and gain valuable insights for future innovation.

Complete machining with a modular system

All this creates the ideal conditions for a common step: developing a flexible production system that allows complete machining for both small batches and medium-sized production runs. EMCO's modular solutions, which can be combined in many different ways, form the basis of this philosophy. The goal is to manage a fully digitalised production process using modular standard elements.

After years of excellent collaboration, we are delighted that EVVA will be accompanying us on this new step in our production development. Our expertise in digitalisation has enabled us to offer a concept that has fully convinced the customer.

Ing. Leopold Zerz, Sales Director Austria, EMCO

Hyperturn Powermill as a base

After joint analysis and testing, the choice fell on a Hyperturn 65 Powermill with an 18,000 rpm spindle, BMT turret and 80-tool chain magazine. Everything is managed by an EMCONNECT interface customised to EVVA's requirements. Optical lines integrated into all axes ensure precision, while an automatic bar feeder optimises loading times and costs.

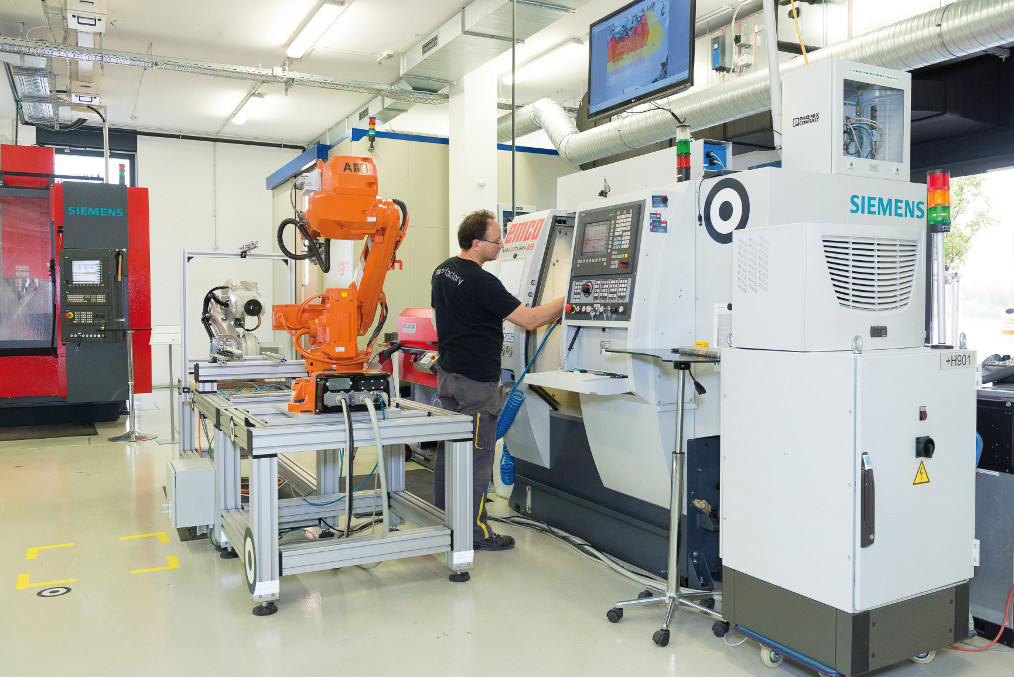

Innovative and interacting robot

A distinctive feature is the use of a cobot: a collaborative robot capable of interacting with operators. Integrated via a dedicated interface, it allows special orders to be managed efficiently. Thanks to its lightweight and intuitive design, it is quick to configure and, during production peaks, can also handle less complex standard processes.

Focus on sustainability and clean production

Sustainability was a key consideration in the design of the system. Dry processing reduces or even eliminates the use of refrigerants and lubricants. The components do not require cleaning, as no aggressive agents that could damage the materials are used. This results in lower consumption, fewer additional steps and a concrete contribution to EVVA's clean production strategy.