Universal Machining Centre Ecomill S

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | X=3000-14000, Y=1300, Z=2000 mm |

| Number of axes (basic machine) | 3+2 |

| Rapid motion speeds in X/Y/Z | 30 m/min |

Tool change

| Number of tool stations | 40/60 pockets |

Highlights

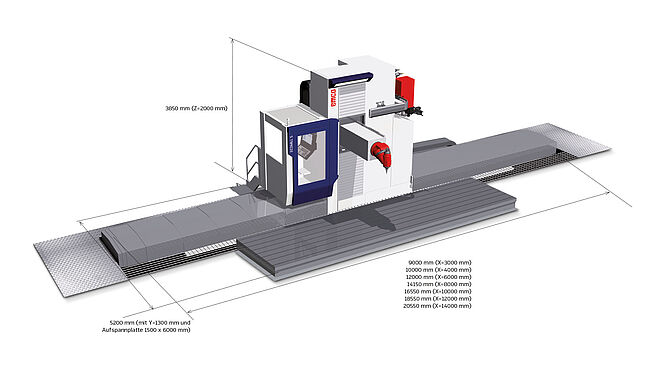

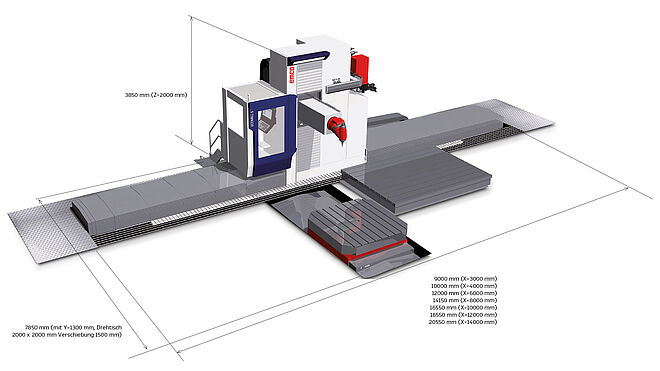

Overall dimensions/Work space

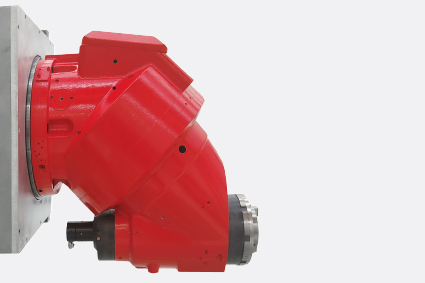

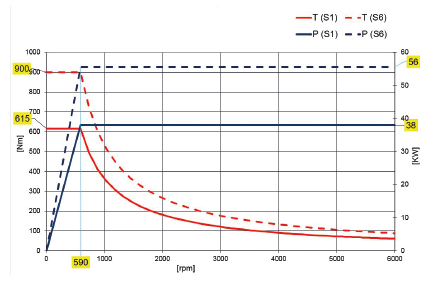

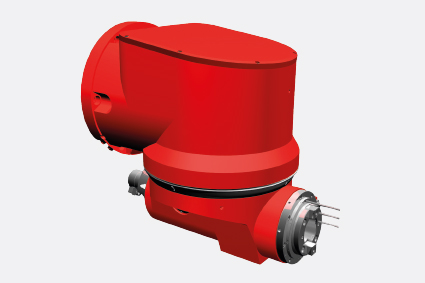

Milling heads

Universal milling head with automatic millesimal positioning and torque motor

General engineering - energy - automotive - aerospace - railway - earthmoving - naval - construction machinery and agricultureMilling head with offset spindle up to 1200 Nm

Plastic and sheet metal moulds - automotive - aerospaceOrthogonal milling head

General engineering - energy - automotive - aerospace - railway - earthmoving - naval - construction machinery and agricultureOptions/Accessories

LASER

Laser tool setting systme positioned on the top of the machine column, in a safe position against debris and possible crashes.ROTARY TABLES

Rotary or turning tables can be installed in any plate size and load capacity, even in combination with pendular mode.Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

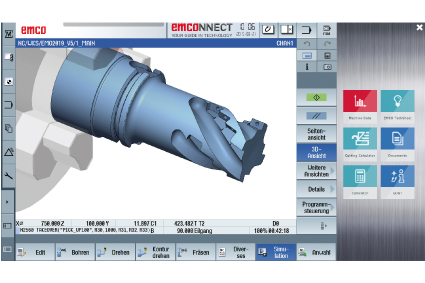

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Steuerungen/Heidenhain/TNC7_MC366_TE361_g_1.0_en_office.png)

Heidenhain TNC 7

With the new TNC7 control from HEIDENHAIN, users and machine tool builders experience completely new possibilities in the programming and operation of their machines.

Because operation is intuitive, task-oriented and customised, making work in the workshop faster, safer and more pleasant.

Highlights of the Heidenhain TNC 7:

- 24 control loops, 4 of which are spindles

- Very high operating dynamics and fluid, intuitive multi-touch operation

- Milling and turning operations

- Intuitive set-up of workpieces with smart probing functions

- Graphically supported alignment of clamping devices

- Short block processing time (0.5 ms)

- High-end performance for perfect surfaces and highest accuracy

- Integrated process monitoring