Emcomat FB-3

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | 300/200/350 mm |

| Distance spindle nose | 80-430 mm |

| Rapid motion speeds in X/Y/Z | X/Y: 1200 mm/min / manually |

| Work feed X/Y/Z | 50-550 mm/min / manually |

| Feed force in X/Y/Z | 8 kN |

| Clamping area | 600x200 mm (rigid angle table) |

| Max. table load | 50 kg (rigid angle table) |

Vertical milling head

| Speed range | 80-2200 rpm |

| Power | 1,4 kW |

| Tool chuck | SK30 DIN2080 |

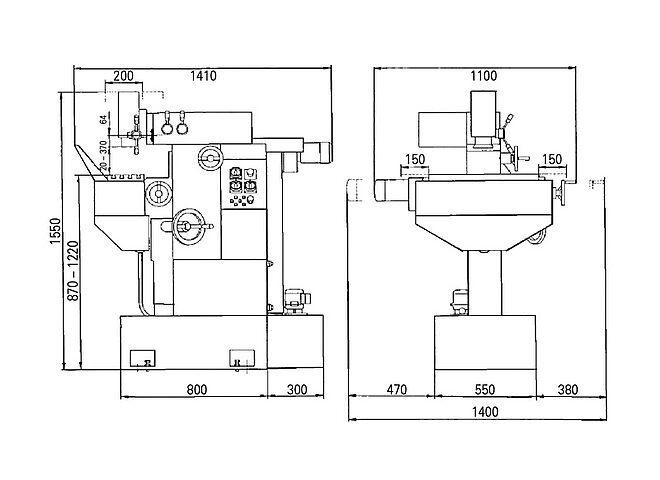

General data

| Dimensions (LxWxH) | 1410x1150x1550 mm |

| Machine weight | 500 kg |

Highlights

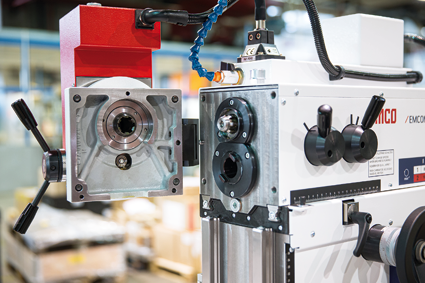

Horizontal Milling Head

Horizontal millingspindle with DIN 2080 SK 30 tool chuck. Swivel-mounted vertical milling head. Vertical-headdrive with palloid tooth system.

Vertical milling head

Vertical milling head with DIN 2080 SK 30 and clampable 45 mm quill travel. The vertical milling head swivels +/- 90°.

CONTROL PANEL

Control panel with ergonomically designed keypad and a swivel mounted position display for easy operation.SAFETY HANDWHEELS (X/Y)

Ergonomically placed handwheels ensure easy and safe handling in all three axes.Overall dimensions/Work space

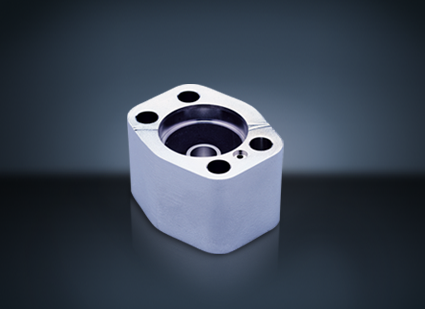

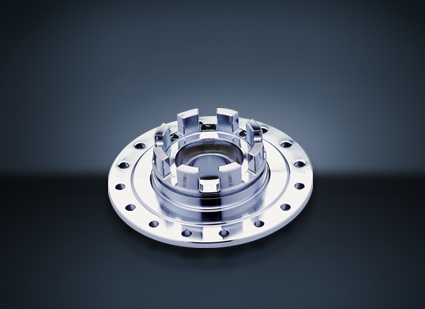

Workpieces

Examples of use

Options/Accessories

Software/Control

Heidenhain ND 70713

The ND 7013 offers many useful functions for machining with manually operated machine tools. Intuitive operating elements and plain-language information in various languages enable context-sensitive operation. In MDI mode, users enjoy graphical positioning support for machining various block types. In distance-to-go mode, the user simply enters the next nominal milling position until reaching zero. Users enjoy a wide range of additional functions:

- Probing functions for reference-point acquisition

- Tool table with tool data

- Positioning support and block types in manual MDI mode

- Tool radius compensation

- Switching functions for simple automation tasks

- Execution of machining patterns

- Cutting data calculator

Heidenhain POSITIP 8016

The POSITIP 8016 offers many useful functions for machining with manually operated machine tools with up to three NC-controlled axes. Intuitive operating elements and plain-language information in various languages enable context-sensitive operation. The user can create, manage, and run programs for recurring jobs directly on the POSITIP 8016. Programs are created from a sequence of machining blocks or patterns. A help wizard guides users through each programming step. An extensive range of additional functions are available as well:

- Probing functions for reference-point acquisition

- Tool table with tool data

- Positioning support and block types in manual MDI mode

- Switching functions for simple automation tasks

- Execution of machining patterns

- Cutting data calculator and spindle-speed control