Concept Mill 260

EQUIPMENT

Technical data

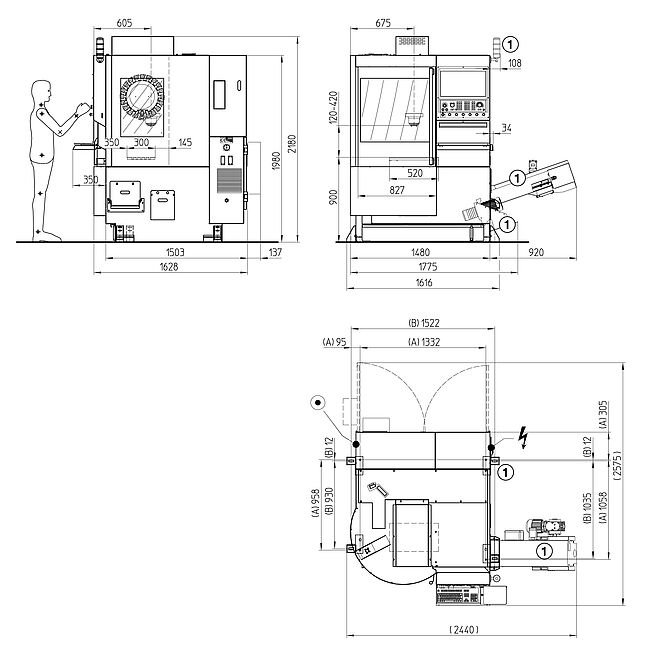

Work area

| Travel in X/Y/Z | 350/250/300 mm |

| Distance spindle nose | 120 - 420 mm |

| Rapid motion speeds in X/Y/Z | 24 m/min |

| Work feed X/Y/Z | 0-10 m/min |

| Feed force in X/Y/Z | 3000 |

| Clamping area | 520 x 300 mm |

| Max. table load | 100 kg |

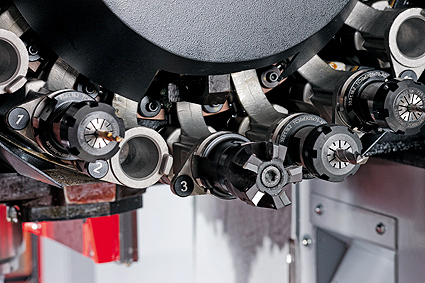

Tool change

| Number of tool stations | 20 |

| Max. tool diameter | 80 mm |

Milling spindle

| Max. speed | 10000 U/min |

| Max. torque | 34 Nm |

General data

| Dimensions (LxWxH) | 1600 x 1700 x 2200 mm |

| Machine weight | 1970 kg |

Highlights

Overall dimensions/Work space

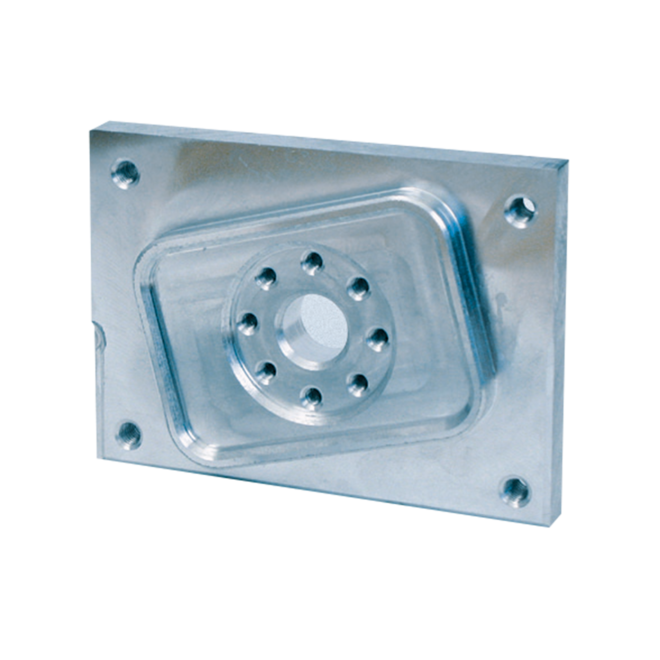

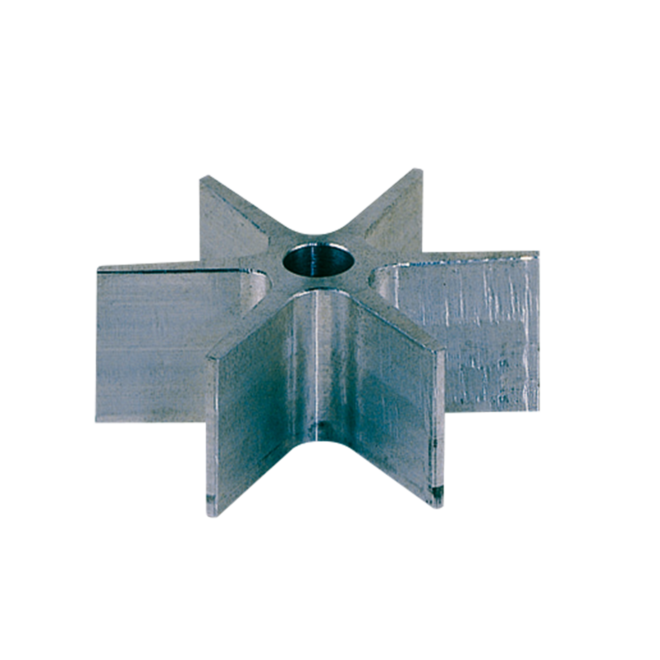

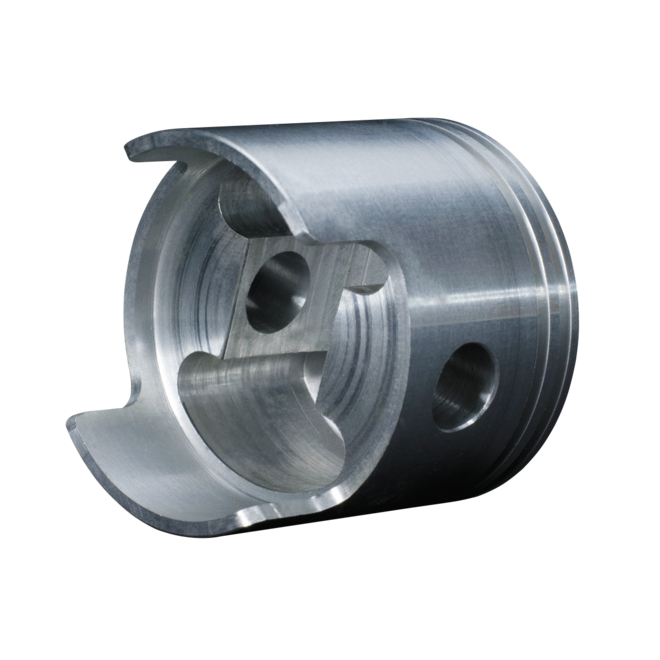

Workpieces

Examples of use

Options/Accessories

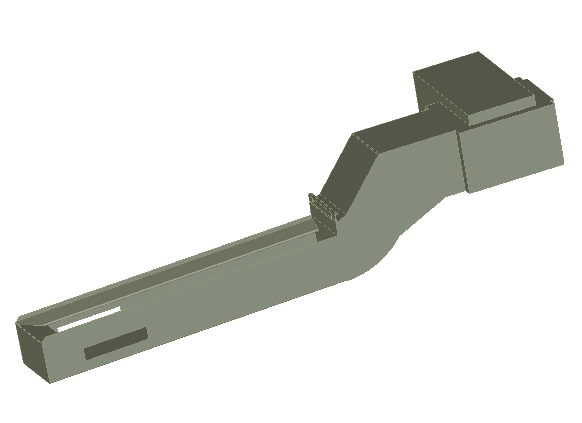

Chip conveyer

Hinge belt conveyer with ejection height 1200 mm, suitable for dry and wet machining; for long steel chips, turning balls and turning wools.Rotating and swivelling unit

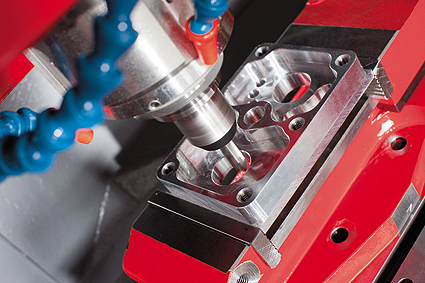

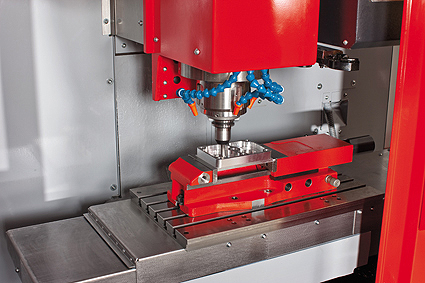

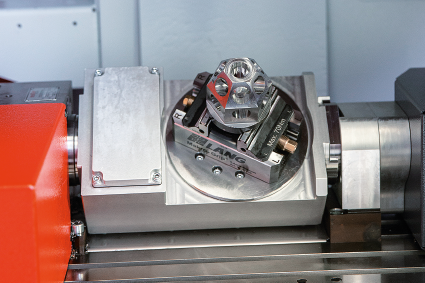

Understanding the technology behind 5-side machining forms an important part of modern training and development programs. With the CONCEPT MILL 260 and the rotating and swiveling unit , EMCO offers a high quality and cost-effective introduction to 5 side milling. The package is also of interest to manufacturing companies in the jewelry and watch-making industry, as well as for mold-making, prototyping, and model manufacturing.

Automation

Automatic Door

Thanks to the pneumatic unit the machine door opens and closes automatically or by pressing the button. The monitoring of the door position is done via end switch

Integration into FMS or CIM systems trough DNC- and Robotic-Interface

The robotics interface can not only control the peripheral equipment (such as automatic door, vice, etc.) but also connect the machine to other machines or devices (e.g. loading and unloading robots). The DNC interface allows programs to be started from the master computer.Software/Control

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Training_Software/winnc_und_erweiterungen/emco-winnc.png)

EMCO WinNC

The unique concept of the interchangeable control can be fitted to all Concept machines. In doing so, the user is trained on all CNC industry controls that are common to the market.

The result: CNC technicians are flexible to work in a variety of settings.

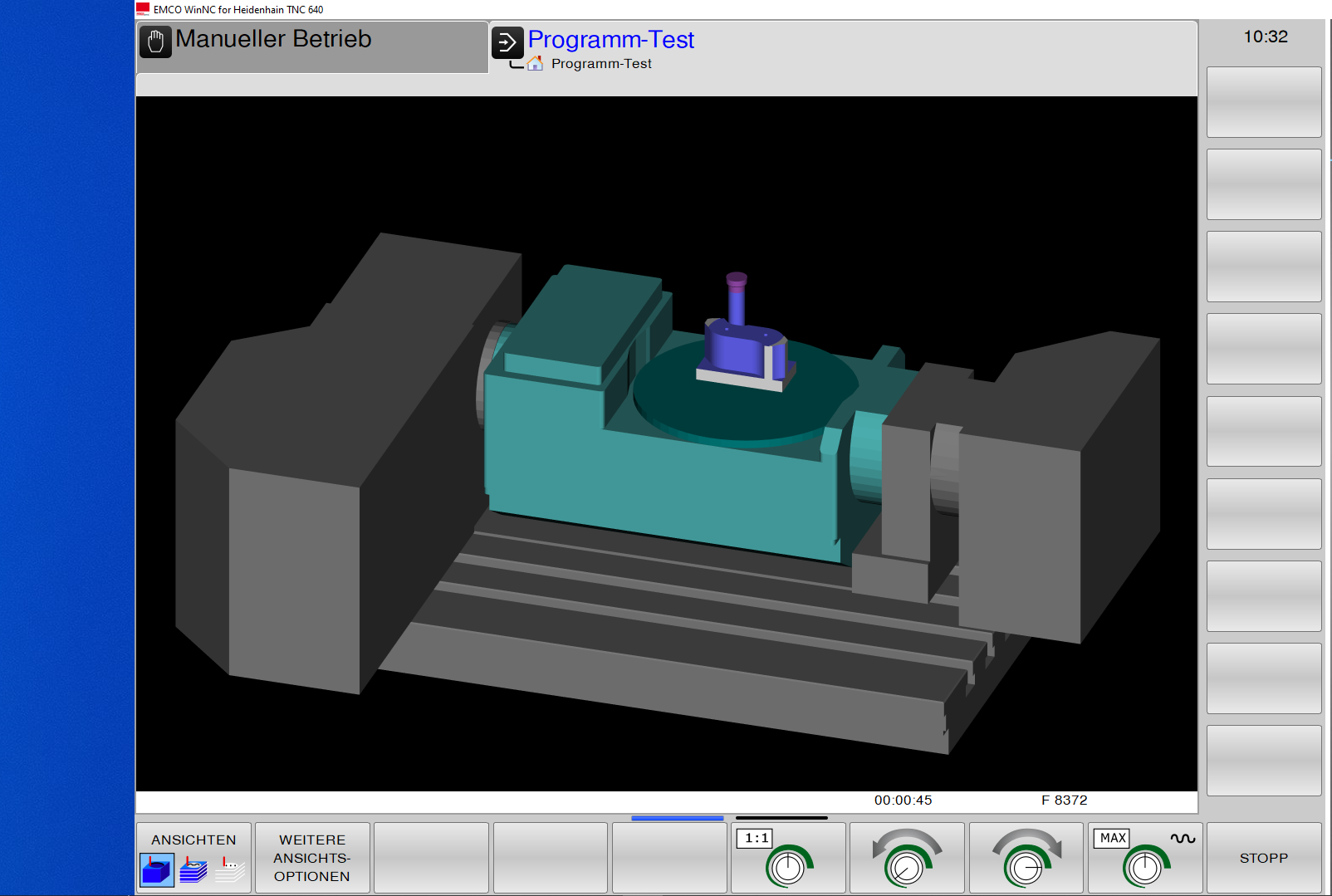

EMCO Win3D-View

Win3D-View is a 3D simulation for turning and milling and is available as an option in addition to the WinNC Control. Graphic simulations of CNC controls are designed especially for industrial experience. Win3D-View displays exceed industry standards. Tools, blanks, clamping devices, and work processes are highly realistic. The system checks the programmed travel of the tool to prevent collision with clamping devices and blanks.

![[Translate to en:] Concept Mill 260](/fileadmin/_processed_/d/0/csm_emco-faesmaschine-ausbildung-milling-machine-training-concept-mill-cm260_01_83c0121135.png)