Emcomat FB-450 MC

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | 450/350/400 mm |

| Distance spindle nose | 230-630 mm (Horizontal milling spindle) |

| Rapid motion speeds in X/Y/Z | 5000/5000/5000 mm/min |

| Work feed X/Y/Z | 10-2000 mm/min stepless |

| Feed force in X/Y/Z | 10/10/15 kN |

| Clamping area | 800x400 mm (rigid angle table) |

| Max. table load | 300 kg (rigid angle table) |

Vertical milling head

| Speed range | 10-5000 rpm |

| Power | 10 kW |

General data

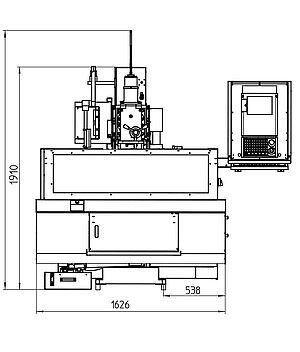

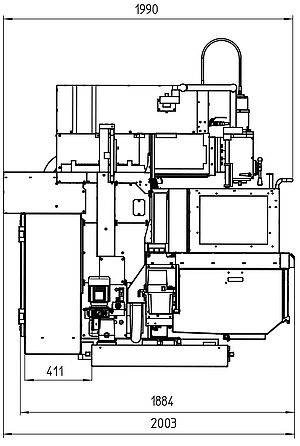

| Dimensions (LxWxH) | 1980x2030x1990 mm |

| Machine weight | 2270 kg |

Highlights

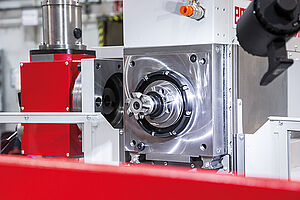

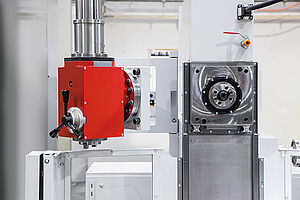

Swivel-Mounted Vertical Milling Head

Swiveling vertical milling head with quill function for manual Drilling operations. A swivel range of +/-90° allows to easily perform even difficult machining operations.

Chip shield

A large chip shield at the front of the machine allows for trouble-free chip disposal.

Overall dimensions/Work space

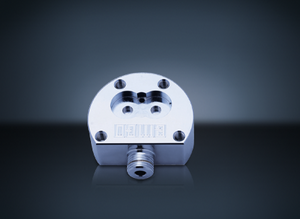

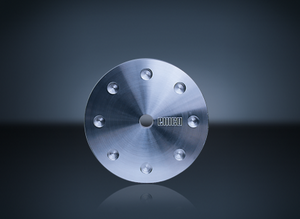

Workpieces

Examples of use

Software/Control

Sinumerik 828D with Manueller Maschine

The Manual Machine operating area provides you with machining capabilities as for a cycle milling machine. All important machining

actions can be performed without an associated part program

needing to be created.

The following functions are available:

- Measure tool

- Traverse axes

- Set zero offset (ZO)

- Drill, such as centered drilling, centering, deep-hole drilling

- Mill, such as face milling, pocket milling, multi-edge stud milling

- Mill contour

User-friendly input screens with help screens and animated elements are available for parameterizing the cycles.

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Steuerungen/Heidenhain/Heidenhain_TNC620_Steuerung.jpg)

Heidenhain TNC 620

With 19" screen for multi-touch operation.

Is a compact, versatile contouring control with three controlled axes and one controlled spindle.

- Programme input with HEIDENHAIN conversational programming and according to DIN/ISO

- Radius/length tool compensation in several tool charts

- Contour elements and free contour programming

- Drilling cycles: tapping, deep drilling, grating, lowering etc.

- Milling cycles: pockets, notches, contouring, multi-pass milling, thread milling, etc.

- Coordinate transformation

- Programming assistance

- Teach-in

- Touch probe cycles