CNC Milling Machine Maxxmill 630

Technical data

Work area

| Travel in X/Y/Z | 500+50/460/450 mm |

| Distance spindle nose | 175/625 mm |

| Rapid motion speeds in X/Y/Z | 30/30/30 m/min |

| Work feed X/Y/Z | 15/15/15 m/min |

| Feed force in X/Y/Z | 5000/5000/5000 N |

| Table | 630x500 mm |

| Max. table load | 200 kg |

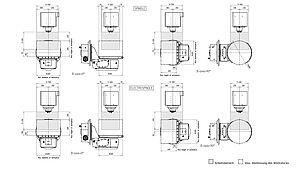

Motor spindle

| Max. speed | 50-15000 rpm |

| Drive power | 20 kW |

| Max. Torque | 100 Nm |

Mechanical Spindle

| Max. Speed | 50-12000 rpm |

| Drive Power (S6) | 15 kW |

| Max. Torque (S6) | 100 Nm |

Tool turret

| Number of tools | 30/60 |

General data

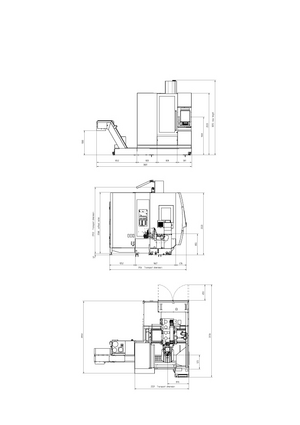

| Dimensions (LxWxH) | 2630x3200x2900 mm |

| Machine weight | 6500 kg |

Highlights

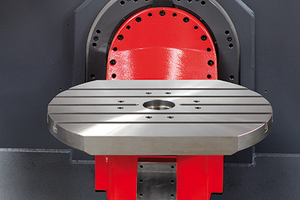

Swivel-rotary-table

The swivel-rotary table has a large clamping area of 630 x 500 mm (24.8 x 19.6") and can bear loads of up to 250 kg (551.1 lb). This makes it possible to simply machine workpieces with an edge size of 445 x 445 x 290 mm (17.5 x 17.5 x 11.4"). The special shape of the table allows the spindles to move closer to the table center.

Travel Range

With a travel range of +/- 100°, the B axis provides a larger work area than most products from other manufacturers. The C axis can be infinitely rotated by 360°.

Direct Drive on the Z axis

The direct drive on the Z-axis stands for highest accuracy and prevents any play of pulleys or belts.Overall dimensions/Work space

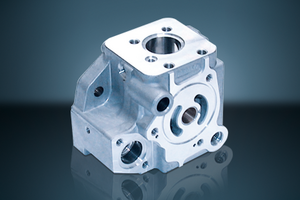

Workpieces

Options/Accessories

Laser device for presetting, breakage check and profile measuring tools

A light barrier mounted on machine table scans the tool edges and automatically takes over the values into the tool offset memory for further processing.Automatic workpiece measuring

The workpieces are automatically measured by an infrared measuring probe that is mounted on the main spindle. Measuring cycles take over the values.Increased coolant pressure with internal coolant supply

A swivel guide with a coolant pump with 20 bar cools spindle and tools.Alternatively cooling by air is possible.

Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

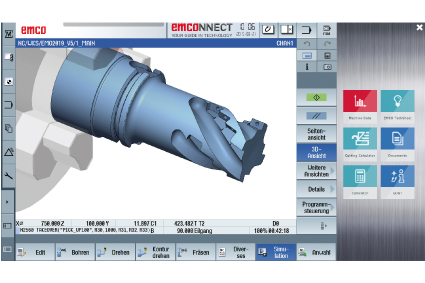

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

EMCONNECT - Digital Process Assistant

For increased productivity and efficiency in production.

EMCONNECT facilitates easy access to digital production – all important information and systems are accessed centrally on the machine. The familiar NC control and hence the familiar operation of the machine remain unchanged.

A clear and compact overview of the machine state, the machine data and the operating mode is available at a glance thanks to the emcoNNECT Dashboard. The hardware basis of the EMCONNECT control centre is a 22“ multi-touch display teamed with an industrial PC and a keyboard including HMI hotkeys for easy and intuitive operation via a user interface optimised for touchscreen use.

Included as standard equipment in the Siemens machine version (Sinumerik ONE).

Heidenhain TNC 620

The latest control offers milling operations, a 19'' TFT colour display and 3D-reproduction and programming graphics.

It is particularly suitable for Mill, HSC- and 5 axis operations at machines up to 6 axes.