Emcomat-20 D

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | 220 / - / 1010 mm |

| Distance between centers | 1000 mm |

| Distance above centers | 200 mm |

Main spindle

| Max. speed | 3000 rpm |

| Spindle nose | DIN 55029 |

| Max. drive power | 5.3 kW |

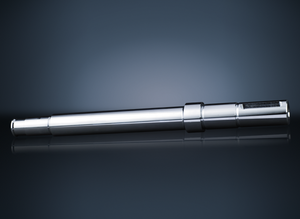

Tailstock

| Quill diameter | 50 mm |

| Inner cone | MT3 |

| Quill travel | 120 mm |

General data

| Dimensions (LxWxH) | 1650/1950 x 1060 x 1635 mm |

| Machine weight | 865 kg |

Highlights

Safety

For the safety of the operator, the chuck protection and wheel caps are monitored by an electric switch.Machine bed

The machine bed`s diagonal ribbing ensures optimal dropping of the chips and that the machines are rigid. The guideways are hardened and grinded.Machine Stand

The machine stand absorbs vibrations. Slanted collection plates make cleaning easy and allow coolant to drain quickly.Workpieces

Examples of use

Options/Accessories

MACHINE DRAWER

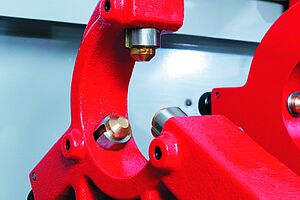

A wide variety of tool holders and other machine parts can be stored in the machine drawer.FAST-CHANGE TOOL HOLDER

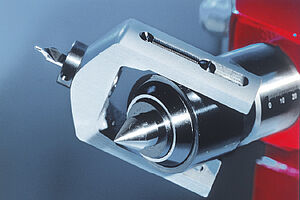

To speed up the machining process, there are several tool holding systems available. This ensures that tools can be changed quickly.CENTER DRILL ATTACHMENT FOR LIVE CENTERS

The center drill attachment enables a quick change between center and support.Software/Control

![[Translate to en:] [Translate to en:]](/fileadmin/user_upload/_Group/pics_products/Emcomat/EM14-20D/App_Bilder_Video/pic_425x283_EM17-20D.jpg)

EMCO 3 axes position display (turning)

The EMCO 3 axes position display showing the X, Z and Zo axis permanently on the TFT screen. The registration of the axes positions is done via linear scales or encoder, respectively, with an accuracy of 0.001 mm.

Functions: permanent display of X/Z/Zo, constant cutting speed, 999 tools, 999 reference points, home position, remaining travel, imperial/metric, radius/diameter display, single or total display for Z and Zo.

Languages: German, English, Spanish, Italian, Dutch, French, Czech.

Screen size 6.5“ color TFT, 640 x 480 resolution (VGA)

The newest version of the respective software can be downloaded here.

For more information about the EMCO 3 axes positioning display, click here.