Universal Machining Center UMILL 1500

Technical data

Work area

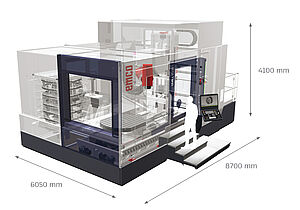

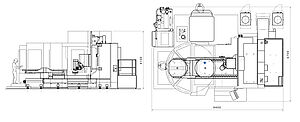

| Travel in X/Y/Z | 1500 / 1500 / 1100 mm |

| Axes feed rate | 60 m/min |

| Max. table load | Rotary table-milling op. 6000 kg / milling + turning 3500 kg |

Highlights

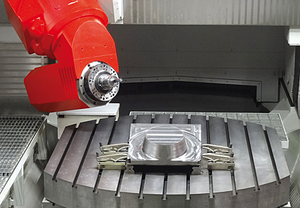

5-Axis machining in one set-up

5-Axis machining in one set-up. Easily accessible work space. Large door openings for workpiece inspection and setup. Easy loading and unloading thanks to the loading door that provides free access from above and opens automatically.

Overall dimensions/Work space

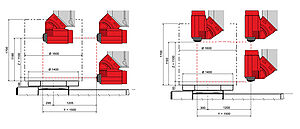

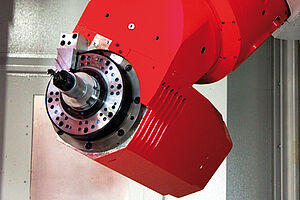

Milling heads

Electric spindle

Compact design with high-performance electric spindle. Continuously variable universal head offering high dynamics for simultaneous machining in connection with the NC rotary table.

Mechanical spindle

Powerful mechanical spindle with high torque and high rigidity for heavy-duty and multi-sided machining in one setup.Software/Control

Siemens 840D sl for Mecof

The NC Siemens 840D Solution Line allows the optimization of the control and drivers parameters to get the highest performances during the high speed machining.

Heidenhain TNC 640 HSCI

The Heidenhain control unit is designed to simplify programming in the shop floor, providing an interactive programming environment, where the operator communicates with the control system through clear and easily comprehensible language.

The Heidenhain control unit is compatible with DIN/ISO programming standards.

EMCONNECT - Digital Process Assistant

For increased productivity and efficiency in production.

EMCONNECT facilitates easy access to digital production – all important information and systems are accessed centrally on the machine. The familiar NC control and hence the familiar operation of the machine remain unchanged.

A clear and compact overview of the machine state, the machine data and the operating mode is available at a glance thanks to the emcoNNECT Dashboard. The hardware basis of the EMCONNECT control centre is a 22“ multi-touch display teamed with an industrial PC and a keyboard including HMI hotkeys for easy and intuitive operation via a user interface optimised for touchscreen use.

Included as standard equipment in the Siemens machine version (Sinumerik ONE).