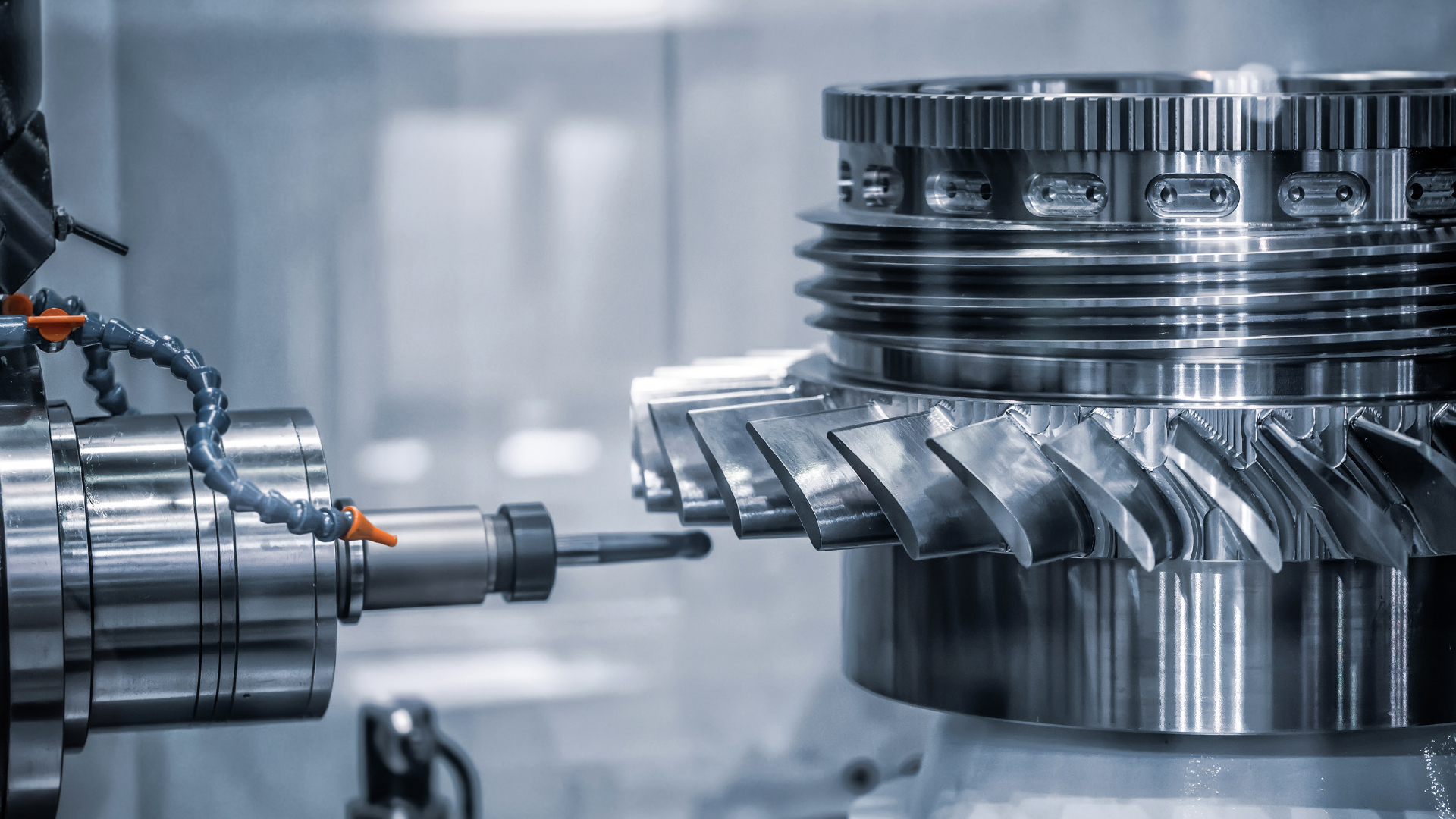

For over 75 years, EMCO has stood for state-of-the-art technology and innovation in the manufacturing industry. Our high-performance machines, the HYPERTURN 45 and the UMILL 630, enable you to manufacture complex workpieces highly productively and efficiently. Whether turning or milling - these versatile all-rounders are unbeatable in their class. And at an unbeatable price!

MORE PUNCH FOR YOUR PRODUCTION

BECOME A SALES AND SAVINGS CHAMPION!

Increase your production efficiency and reduce costs at the same time.

- Highly productive: Manufacture complex workpieces with maximum precision.

- Efficient: Maximise your production capacities.

- Cost-effective: Utilise immense savings potential.

For more turnover. For better results. For a stronger market position.

You can find all the benefits and technical features at: www.allrounder-champions.com

Your future at EMCO - Apply now!

EMCO has been a leading manufacturer of lathes and milling machines for over 75 years and offers a wide range of development opportunities. From competent technician to business specialist: there are many paths open at EMCO for committed employees who are willing to undergo further training. Become part of an innovative team and shape the future of manufacturing technology with us.

Vacancies: Discover our current job vacancies and start your career at EMCO.