Maxxturn 45 G2

EQUIPMENT

Technical data

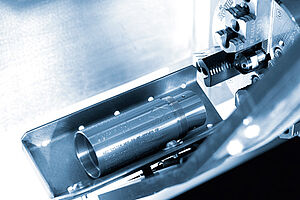

Work area

| Travel in X/Y/Z | 160/70/510 mm |

| Bar diameter | Ø 45 (51) mm |

| Max. turning diameter | Ø 300 mm |

| Swing over bed | 430 mm |

| Spindle distance | 720 mm |

Main spindle

| Max. speed | 0-7000 rpm |

| Max. drive power | 15 kW |

| Max. torque | 100 Nm |

Counter spindle

| Max. speed | 0-7000 rpm |

| Max. drive power | 15 kW |

| Max. torque | 100 Nm |

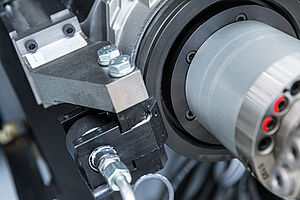

Tool turret

| VDI size | VDI 25 |

| Number of tools | 12 |

| Driven tools | 12 |

| Max. speed | 0-8000 rpm |

| Max. drive power | 4 kW |

| Max. torque | 16 Nm |

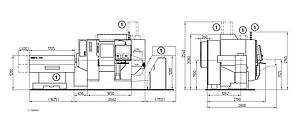

General data

| Dimensions (LxWxH) | 2662 x 1790 x 2080 mm |

| Machine weight | 4000 kg |

Highlights

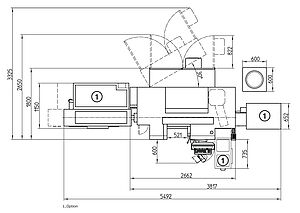

Overall dimensions/Work space

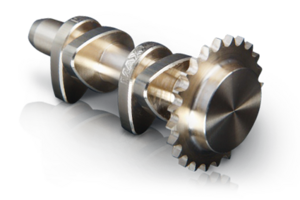

Workpieces

Automation

Swing loader

Universal loading and unloading for preformed blanks and parts.

Using the multiple grippers and handling systems the swing loader can be customized to your individual needs.

Short-bar loader EMCO SL 1200

The EMCO short-bar loader SL 1200 is the perfect solution for the automatic reloading of pre-cut bars up to 1200 mm.

The adavantage: small footprint and short loading times through shorter strokes.

The control unit is perfectly adapted to the interface of the machine.

Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

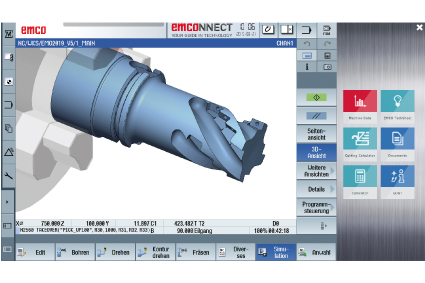

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

Fanuc 31i-B

Their enhanced functionality and superior performance extends the potential of machine capabilities into the future. The product line spans from standard CNC applications up to the most complex machine tools and non-traditional applications. FANUC controls have a world-class reputation

for performance, precision, reliability and user-friendly operation, making them popular with the most demanding managers and operators alike. With more than 2.2 million controls already installed around the

globe, FANUC is the world’s leading CNC manufacturer. By choosing a machine tool with a FANUC CNC it will be available for production more often, process more parts and use less energy.

- Compatibility with all predecessor CNC versions

- Minimal integration required. Existing programs run without new/reprogramming

- Simple parts programming through fixed cycles and customer macros

This is complemented by the easy to use MANUAL GUIDE i Dialog Programming - Easy operation through a user-friendly graphics display for visual parts program checks

- Extensive help functions

- Interpolation in the nanometer range for the highest surface quality.

- Ethernet connectivity:

CNC screens allow the operator to display parts programs which are saved in an FTP server directory and to load selected files onto the machine. Alternatively, files can be loaded onto the machine from a remote office with the parts program transfer tool with .

drag & drop.

EMCONNECT - Digital Process Assistant

For increased productivity and efficiency in production.

EMCONNECT facilitates easy access to digital production – all important information and systems are accessed centrally on the machine. The familiar NC control and hence the familiar operation of the machine remain unchanged.

A clear and compact overview of the machine state, the machine data and the operating mode is available at a glance thanks to the emcoNNECT Dashboard. The hardware basis of the EMCONNECT control centre is a 22“ multi-touch display teamed with an industrial PC and a keyboard including HMI hotkeys for easy and intuitive operation via a user interface optimised for touchscreen use.

Included as standard equipment in the Siemens machine version (Sinumerik ONE).