Emcomill E350

EQUIPMENT

Technical data

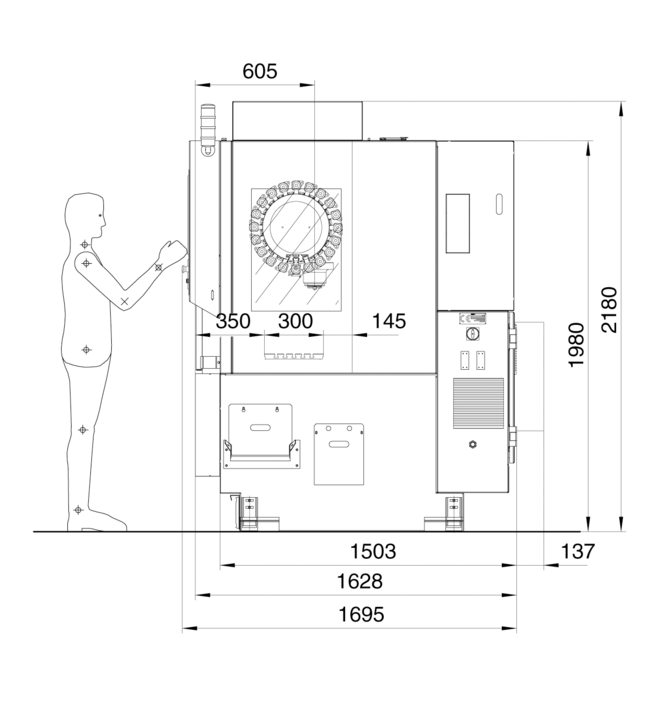

Work area

| Travel in X/Y/Z | 350/250/300 mm |

| Distance spindle nose | 120-420 mm |

| Rapid motion speeds in X/Y/Z | 24/24/24 m/min |

| Clamping area | 520x300 mm |

| Max. table load | 100 kg |

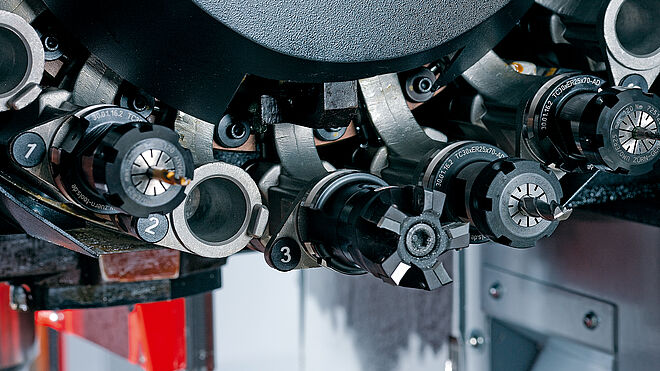

Tool change

| Number of tool stations | 20 |

| Tool changing time (tool to tool) | 2,5 s |

| Max. tool diameter | 63 (80) mm |

| Max. tool length | 200 mm |

Milling spindle

| Max. speed | 10000 rpm |

| Max. drive power | 6,8 kW (S1) |

| Max. torque | 34 Nm (S6 60%) |

General data

| Dimensions (LxWxH) | 1600x1700x2200 mm |

| Machine weight | 1970 kg |

Highlights

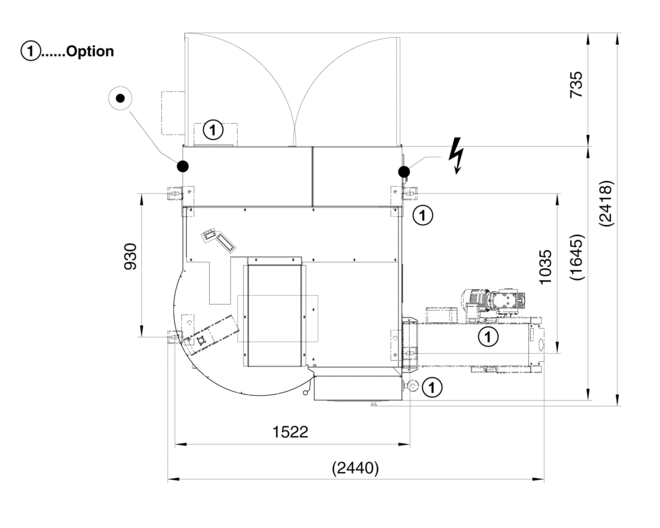

Overall dimensions/Work space

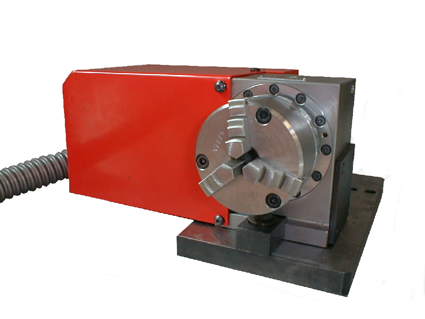

Options/Accessories

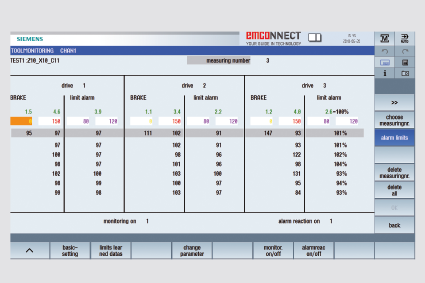

EMCO tool breakage monitoring system

The tool status is monitored by evaluating the load on the various axis drive motors. Excessive loads point to wear or broken tools. Too low a load indicates a tool is missing.

Software/Control

Sinumerik 828D - incl. ShopMill

SINUMERIK 828D: High performance CNC control for ultimate accuracy and machining speed SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art milling machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopMill machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to Advanced Surface, an innovative method of velocity and path control, SINUMERIK 828D also meets the demands of high sophisticated mold & die applications. Source picture and text: Siemens

![[Translate to en:] Emcomill E350](/fileadmin/_processed_/9/d/csm_emco-vertikales-bearbeitungszentrum-cnc-vertcial-machining-center-350_60f6411fc4.png)