Emco Vertical VT 400

Technical data

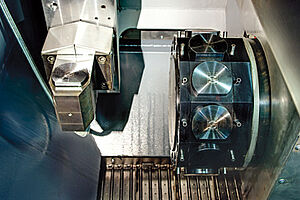

Work area

| Travel in X/Y/Z | 960 / +/- 90 /400 mm |

| Max. turning diameter | 400 mm |

| Swing over bed | 450 mm |

| Rapid motion speeds in X/Y/Z | 45/15/30 m/min |

| Feed force in X/Y/Z | 10.000/10.000/8.500 |

Main spindle

| Max. speed | 4000 rpm |

| Spindle nose | A 11 |

| Max. drive power | 36 kW |

| Max. torque | 600 Nm |

Tool turret

| VDI size | 40 |

| Number of tools | 12 |

| Driven tools | 12 |

| Max. speed | 4000 rpm |

| Max. drive power | 8,5 kW |

| Max. torque | 40 Nm |

General data

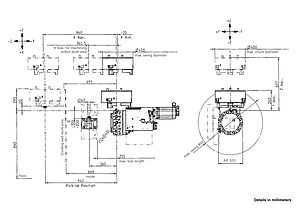

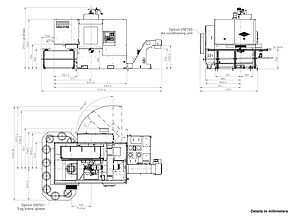

| Dimensions (LxWxH) | 3482 x 2511 x 2939 mm |

| Machine weight | 8500 kg |

Highlights

Vielfältige Automatisierungsmöglichkeiten

Basic machine with driven tools and integrated spindle motorOverall dimensions/Work space

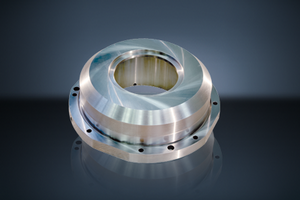

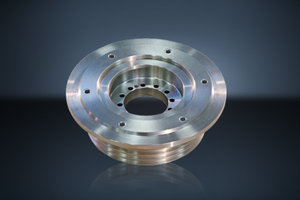

Workpieces

Versions

EMCO Vertical VT 400 MY (ISM)

Basic machine with driven tools, Y axis and integrated spindle motorOptions/Accessories

Automatic workpiece measuring

The workpieces are automatically measured by an infrared measuring probe that is mounted on the main spindle. Measuring cycles take over the values.Software/Control

Sinumerik 828D - incl. ShopTurn

High performance CNC control for ultimate accuracy and machining speed. SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art turning machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopTurn machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to powerful kinematic transformations and a large set of technological cycles, SINUMERIK 828D also meets the demands of high sophisticated machine applications with driven tools and sub-spindle. Source picture and text: Siemens