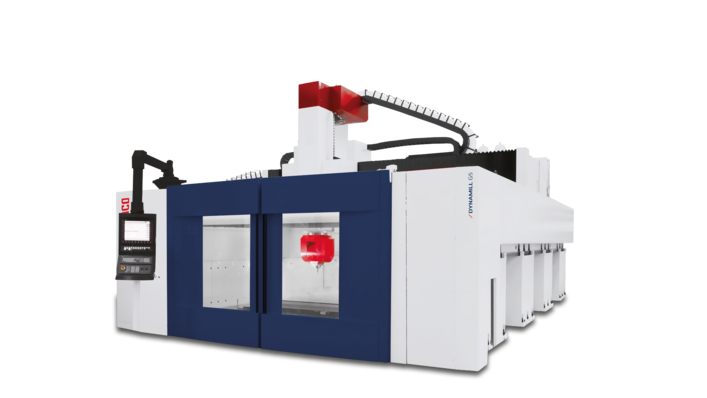

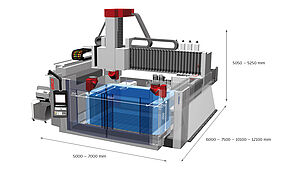

Gantry Milling Machine Dynamill G5

EQUIPMENT

Technical data

Work area

| Travel in X/Y/Z | X 2500/4000/6000/8000 // Y 2200/3500 // Z 1300/1500 mm |

| Axes feed rate | 40 m/min |

Milling spindle

| Number of tools | 24 / 48 / 64 |

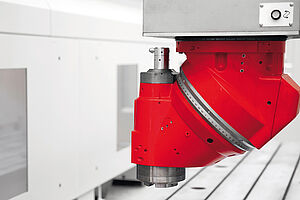

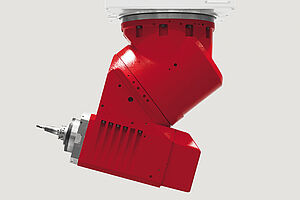

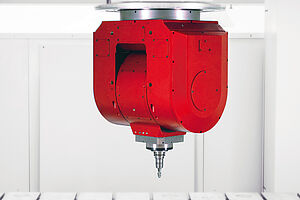

Milling heads

| Universal milling head with automatic millesimal positioning | 38 (S1)/48 (S6) kW // 300 (S1)/373 (S6) Nm //6000 rpm |

Highlights

DIRECT DRIVE 5-AXIS MILLING HEADS BY MECOF DESIGN

/ Milling / Drilling / Tapping / Turning, etc.SUCTION SYSTEM

Dust and fumes can be easily conveyed by Mecof suction system integrated in the fork type milling head.EASILY ACCESSIBLE WORK AREA

Wide sliding doors on the machine front side for easy loading and unloading of large workpieces.TCB6-E / MECOF Design

Universal milling head with automatic millesimal positioning. A powerful mechanical spindle with high torque for heavy-duty machinings.TWT / MECOF Design

Direct drive universal milling head with high-speed spindle. New design 15° undercut makes it more agile in machining of complex workpieces.SP20_SP21 / MECOF Design

Fork type milling head with high-speed spindle and torquemotors. 20° undercut.Overall dimensions/Work space

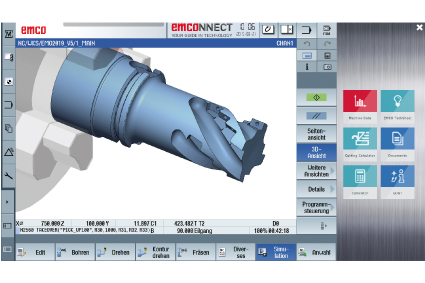

Software/Control

Sinumerik ONE with Operate

The Sinumerik ONE is the universal and flexible CNC system. With a wide range of functionality, it is suitable for use in almost all technologies. The Sinumerik ONE sets standards in terms of dynamics, precision and integrability in networks.

With the Sinumerik ONE you rely on:

- highest performance and flexibility

- universal openness

- highly effective personal and machine protection

Sinumerik & EMCONNECT, the digital process assistant

EMCONNECT is included in the standard machine. Switching between emcoNNECT apps and the control system is possible with a single click. All production-relevant data can be displayed in full-screen or sidebar view.

The new SINUMERIK ONE has been specially developed for smart manufacturing.

- Digital twin is an integral part of the CNC control, virtual and real control merge and complement each other

- Significant reduction in product development and time-to-market thanks to the digital first strategy

- Improved networking and data communication capabilities

- Significant reduction in the duration of real commissioning through virtual preparation for commissioning

- Significantly increased CNC performance

- Significantly shorter non-productive times and complete integration into the TIA Portal through the integrated SIMATIC S7-1500F PLC

This means that the SINUMERIK ONE can be seamlessly integrated into digital solutions and workflows.

Heidenhain TNC 640 HSCI

The Heidenhain control unit is designed to simplify programming in the shop floor, providing an interactive programming environment, where the operator communicates with the control system through clear and easily comprehensible language.

The Heidenhain control unit is compatible with DIN/ISO programming standards.