Maxxturn 25

Technical data

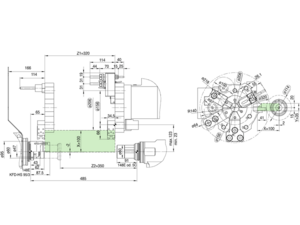

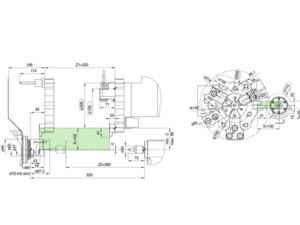

Work area

| Travel in X/Y/Z | 100 / +20 / -15/ 320 mm |

| Bar diameter | 25,4 mm |

| Max. turning diameter | 114 mm |

| Swing over bed | 325 mm |

| Spindle distance | 485 mm |

| Rapid motion speeds in X/Y/Z | 20/10/30 m/min |

Main spindle

| Max. speed | 8000 rpm |

| Spindle nose | Ø70 h5 mm |

| Max. drive power | 6.5 kW |

| Max. torque | 30 Nm |

Counter spindle

| Max. speed | 8000 rpm |

| Spindle nose | Ø70 h5 mm |

| Max. drive power | 3.5 kW |

| Max. torque | 20 Nm |

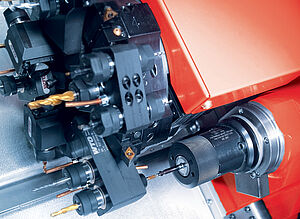

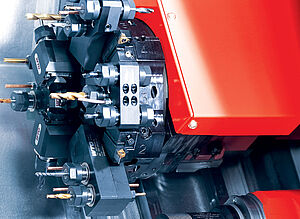

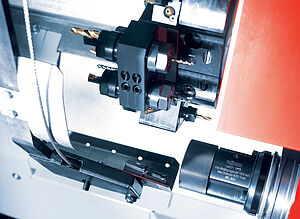

Tool turret

| VDI size | 16 |

| Number of tools | 12 |

| Driven tools | 6 |

| Max. speed | 6000 rpm |

| Max. drive power | 1.2 kW |

| Max. torque | 4 Nm |

General data

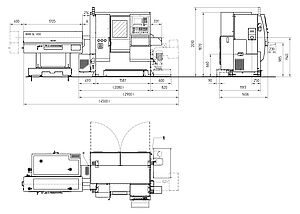

| Dimensions (LxWxH) | 2180 x 1425 x 1870 mm |

| Machine weight | 2100 kg |

Highlights

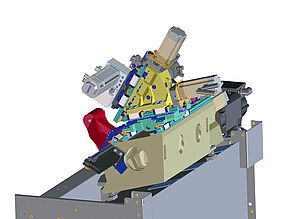

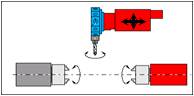

counter spindle

The machine has an extremely compact counter spindle for machining the reverse side. Mounted on guide rails, it can be positioned at 30 m/min. The parts are taken from the main spindle and completed in one process. A speed range of 0 – 8000 rpm provides optimal conditions for turning and drilling. The counter spindle can also be positioned for light milling and drilling operations.machine core

Designed on the basis of FEM analyses, the MAXXTURN 25 meets the high demands of modern machining in an ideal manner. Maintenance-free roller guides in all linear axes ensure high stability and precision. Another advantage is offered by minimum lubricant consumption teamed with long tool lives. When it comes to shaft processing, the machine can be equipped with tailstock or counter spindle. The counter spindle offers the advantage of being able to finish the workpiece completely on all sides. This also includes drilling and milling operations on the rear side.tool turret

Fast, servo turret with 12 VDI 16 position holes. It can be indexed up to 36 positions to increase the number of tools. This means that up to 42 tools can be integrated when using multi-tool holders. The swivelling can be slowed or even stopped to simplify running-in the machine.Overall dimensions/Work space

Workpieces

Examples of use

Versions

Options/Accessories

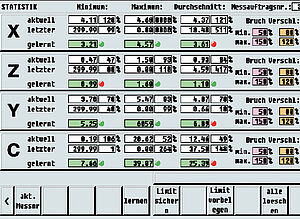

EMCO tool break monitoring

The tool status is monitored by evaluating the load on the various axis drive motors. Excessive load point to tool wear or breakage. Too low load indicates a tool is missing.Finished part conveyer

The finished-part pick-up device places the parts on an accumulating conveyer. The conveyer is timed to prevent the parts, some of which are very complex, from falling on top of each other.Part catcher

Finished parts are transported from the counter spindle to the finished parts container with the aid of the part catcher. This proven EMCO concept with the swiveling catcher ensures optimum access to the working area, free chip flow and careful removal of the finished parts.Software/Control

Fanuc 31i-B

Their enhanced functionality and superior performance extends the potential of machine capabilities into the future. The product line spans from standard CNC applications up to the most complex machine tools and non-traditional applications. FANUC controls have a world-class reputation

for performance, precision, reliability and user-friendly operation, making them popular with the most demanding managers and operators alike. With more than 2.2 million controls already installed around the

globe, FANUC is the world’s leading CNC manufacturer. By choosing a machine tool with a FANUC CNC it will be available for production more often, process more parts and use less energy.

- Compatibility with all predecessor CNC versions

- Minimal integration required. Existing programs run without new/reprogramming

- Simple parts programming through fixed cycles and customer macros

This is complemented by the easy to use MANUAL GUIDE i Dialog Programming - Easy operation through a user-friendly graphics display for visual parts program checks

- Extensive help functions

- Interpolation in the nanometer range for the highest surface quality.

- Ethernet connectivity:

CNC screens allow the operator to display parts programs which are saved in an FTP server directory and to load selected files onto the machine. Alternatively, files can be loaded onto the machine from a remote office with the parts program transfer tool with .

drag & drop.

Sinumerik 828D - incl. ShopTurn

High performance CNC control for ultimate accuracy and machining speed. SINUMERIK 828D and SINAMICS drive and motors are perfectly tailored for state of the art turning machines. Powerful CNC-functions combined with a unique 80bit NANOFP Accuracy (80 bit floating point accuracy from the position control to the internal encoder resolution) enable highest work-piece accuracy at a minimum of machining time. With a flexible CNC programming language and the state of the art ShopTurn machining step programming, single parts as well as large batch series can be programmed and machined with maximum effectiveness. Due to powerful kinematic transformations and a large set of technological cycles, SINUMERIK 828D also meets the demands of high sophisticated machine applications with driven tools and sub-spindle. Source picture and text: Siemens