Heidenhain TNC 426/430

The Heidenhain TNC 426/430 is part of the interchangeable control WinNC.

WinNC allows the user to learn all CNC industry controls that are common on the market on a CONCEPT machine or on a programmers place.

One of these controls is the Heidenhain TNC 426/430.

It corresponds in terms of handling and function to the particular original control and can also be installed on a PC.

The user has the possibility to work on the PC as well as on the machinecontrol and gets familiar with all aspects of control programming in detail.

Highlights

Functions

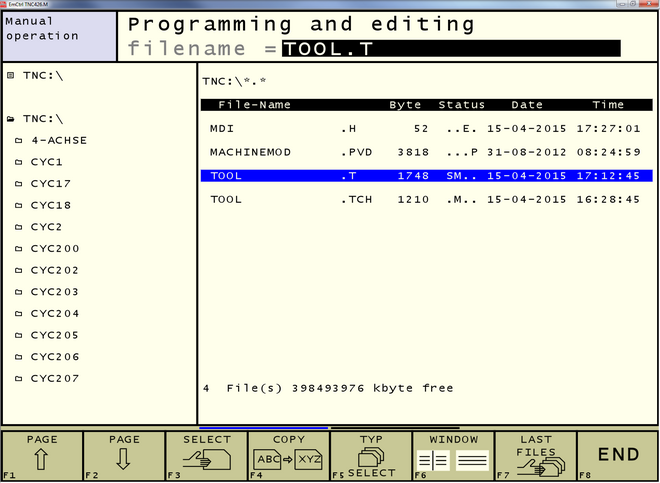

Data in/output of workpiece program files

Workpiece program files can include several main and subprograms and further corresponding tool data. Moreover, workpiece data, R-parameter and zero offsets can be exported and imported.

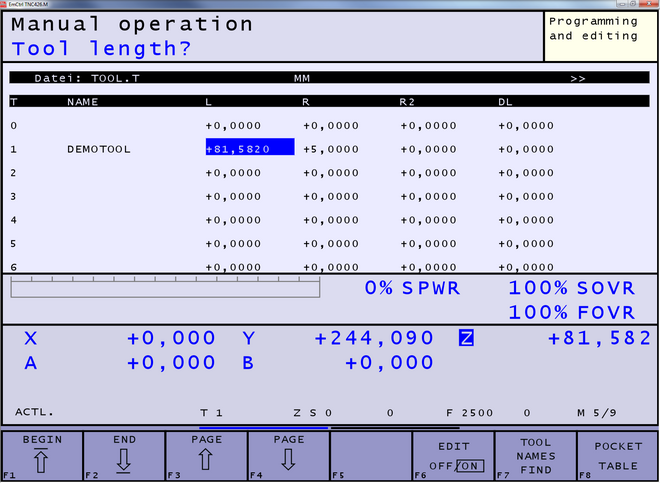

Automatic measuring of tools

When scratching the reference workpiece the workpieces offsets will be taken over.

Automatic measuring of position offsets

When scratching the measured workpiece the position offsets will be taken over.

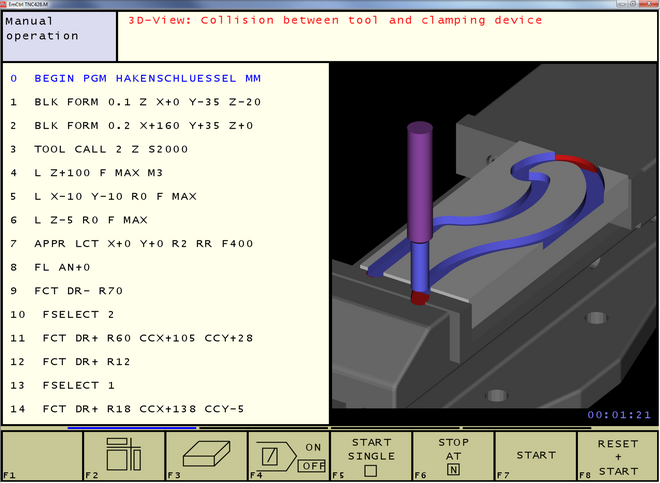

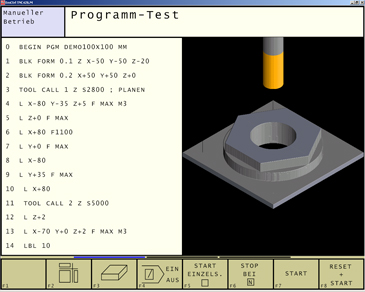

Dry run

In the run-up to the machining process collisions and programming mistakes can be avoided and corrected by using the dry run.

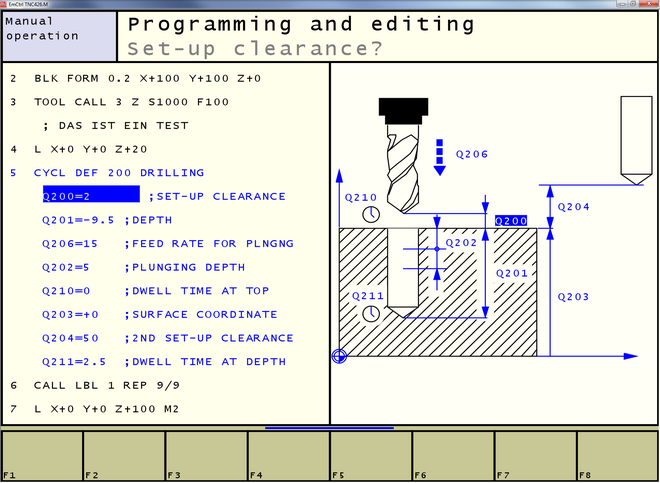

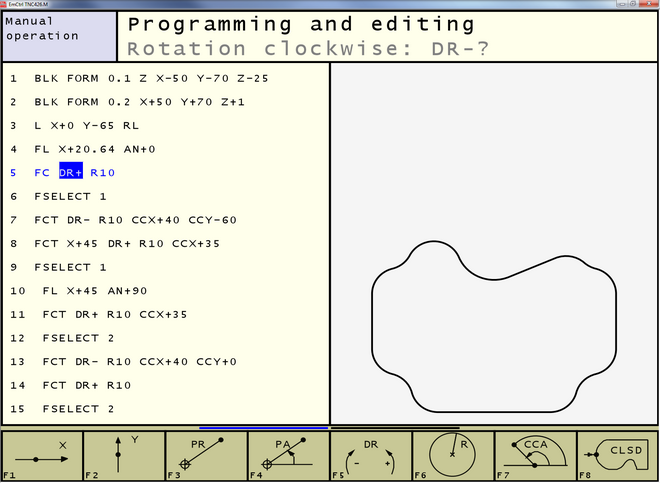

Editor

In order to ease the operation and the programming the control is equipped with an editor with helping cycles and pictures.

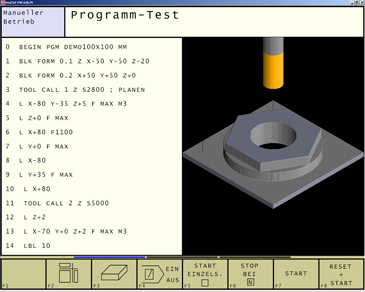

Contour processor with graphic simulation

The contours the workpieces should have after the machining process are illustrated by graphics in the programming process.

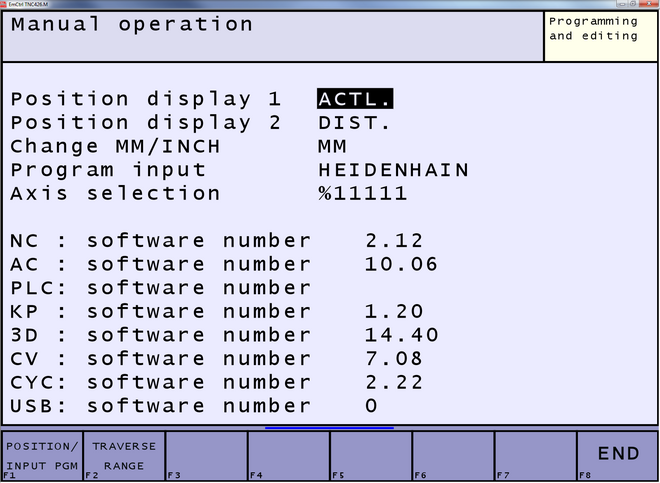

Diagnostics

Alarms, signals, versions and customer information are displayed by the diagnostics.

Downloads

Software-Demos

Software demo / full version / homeschooling

Just give our WinNC software a try! All WinNC controls can be tested as demo versions free of charge and without obligation.

Our DEMO versions contain the full range of functions (only programming stations, direct control of machines is only possible via licensed software), but their useful life is limited to 30 days (from the date of installation).

By entering a valid license key all demo versions can easily converted into a full version or a homeschooling version at any time.

| Title | Version | Filesize | |

|---|---|---|---|

| DEMO | 2.16.0004 | 111 MB | -1 |

Updates/Upgrades

Get up to date. The only requirement is that you have a valid license key. The improvements concerning the update are documented in History.

You are reminded that, in case of an update, all WinNC-components (WinNC-controls, 3DView, DNC, Robotic, CAMConcept,...) located in the regarding directory must be updated to the current release-version.

| Title | Version | Filesize | |

|---|---|---|---|

| UPDATE | 2.16.0004 | 111 MB | -1 |

| Title | Version | Filesize | |

|---|---|---|---|

| short description für update installation | A2014-09 | 415 KB | -1 |

| MSD/PLC | 2025.01.07 | 748 KB | -1 |

| ACpn Update | 1.14.0002 | 244 MB | -1 |

| ACC update | 3.08.0003 | 66 MB | -1 |

| AC95_ACC | 2013.10.15 | 3 MB | -1 |

| AC88_ACC | 2013.10.15 | 3 MB | -1 |

| Remove SPOX | 2006.12.05 | 2 MB | -1 |

Versionhistory

| Version | Date | Changes | ||

|---|---|---|---|---|

| 2.16 | 23.01.2019 | Compatibility WinNC for Heidenhain TNC 640 | ||

| 2.14 | 30.05.2017 | Compatibility WinNC for Heidenhain TNC 640 | ||

| 14.09.2015 | Release for Windows 10 | |||

| 2.12 | 19.12.2014 | Adaption ACpn-machines, Easy2control | ||

| 2.10 | 11.03.2013 | Compatibility 'WinNC for Sinumerik Operate' / Windows8 | ||

| 2.08 | 15.05.2012 | Compatibility 'WinNC for Sinumerik Operate' | ||

| 2.06 | 25.09.2009 | Integration CM250 | ||

| 2.04 | 23.06.2008 | Integration CM450 | ||

| 2.02 | 30.10.2007 | VISTA, industrial strength tool-path-compensation WinConfig replaced by EMConfig | ||

| 1.42 | 03.06.2005 | tool-administration for 3D-View | ||

| 1.38 | 08.02.2008 | Toollength-compensation in Jog-Mode, Bug-fixes M2, M89 | ||

| 1.35 | 02.11.2004 | Update | ||

| 1.32 | 02.06.2004 | Update | ||

| 27.09.2004 | Spanish version | |||

| 1.30 | 05.05.2004 | new SL2-Cycles, new 3D-View, positioning with manual data input | ||

| 1.26 | 02.03.2004 | Revision of the thread-cycles | ||

| 1.25 | 15.01.2003 | Revision of the implemented cycles | ||

| 1.20 | 25.09.2003 | Market launch |

Instructions/Manuals

Hier finden Sie sämtliche Informationen und Hinweise zur Installation und Anwendung der Steuerungsoberfläche.

| Title | Version | Filesize | |

|---|---|---|---|

| Steuerungsdokumentation Fräsen | E2013-12 | 10 MB | 0 |

| control manual milling | E2013-12 | 10 MB | 1 |

| control manual milling (french) | C2004-05 | 5 MB | 2 |

| control manual milling (spanish) | C2004-05 | 4 MB | 5 |

| control manual milling (italian) | D2013-03 | 9 MB | 6 |

| control manual milling (czech) | E2014-06 | 10 MB | 7 |

| Title | Version | Filesize | |

|---|---|---|---|

| startup milling (spanish) | E2008-11 | 2 MB | 5 |

| startup milling (spanish) | E2008-11 | 1 MB | 5 |

| startup milling and turning (italian) | L2019-02 | 972 KB | 6 |

| startup milling and turning (dutch) | L2019-02 | 936 KB | 3 |

| startup milling and turning (french) | L2019-02 | 927 KB | 2 |

| startup milling and turning (czech) | L2019-02 | 969 KB | 7 |

| Inbetriebnahme Drehen und Fräsen | L2019-02 | 1 MB | 0 |

Options/Accessories

Easy2control

“Easy2control” adds a range of attractive applications to the successful interchangeable control system used in EMCO training machines.

Suitable for use in machines and simulation workplaces alike, it displays additional control elements directly on the screen and, when used together with a touchscreen monitor, provides the ideal input interface.

With support for a wide range of keyboard variants, customer-specific screen layouts and tailored solutions for individual customers, Easy2control represents a promising and highly flexible extension to the modular EMCO training concept.

The interchangeable controls are represented using an on-screen keyboard, which makes switching between different control systems even easier and quicker.

In the DEMO version of WinNC, Easy2control can be activated without a license key during the installation process or afterwards using the EMConfig configuration tool.

Easy2operate

Portable Machine Operating panel to operate the machine via hardware, includes axis buttons, feed override switch, mode switch etc. together with EMCO Easy2control.Robotic

Das Robotik-Interface wird für den Anschluss der Concept-Maschinen an den FMS-/CIM-Betrieb benötigt.

For more information about Robotic, click here.

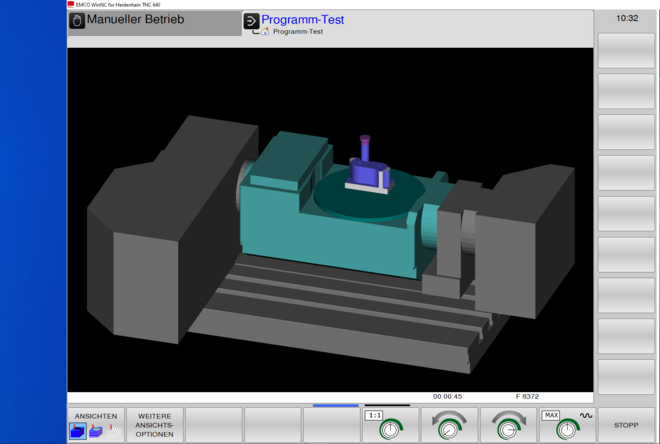

EMCO Win3D-View

Win3D-View is a 3D simulation for turning and milling and is available as an option in addition to the WinNC Control. Graphic simulations of CNC controls are designed especially for industrial experience. Win3D-View displays exceed industry standards. Tools, blanks, clamping devices, and work processes are highly realistic. The system checks the programmed travel of the tool to prevent collision with clamping devices and blanks.

Concept machines

Whether for small businesses or for professional CNC training the Concept machines can be applied flexibly. With its modular concept the machine series can be used in a productional CIM network as well as for training purposes equipped with training softwares and coursewares.

For more information about the Concept machines click "machines" in the main menu.